The NR-2 is developed to replace wet wipes. First reason for us was because they clogged our sewer due to the fact that we were huge fans of wet wipes. We ended up digging out our sewer pipe and completely replaced it as the blockage was too bad to unclog.

At that time i was thinking that it might be an idea to come up with an alternative so i went on an online expedition to see how bad these wet wipes really are......

I WAS SHOCKED!!!!

after seeing this video of THE GUARDIAN...

Turns out that wet wipes are containing plastic and they are not disintegrating like normal toilet paper causing all kinds of horrible disasters like bringing down whole water treatment plants and polluting oceans and beaches.

Wet wipes appear to be jellyfish for marine life like sea turtles so they eat the wet wipes.

Sea turtles eat large numbers of jellyfish. (which look like wet wipes).Researchers at Commonwealth Scientific and Industrial Research Organisation (CSIRO) in Australia found that a turtle had a 22 percent chance of dying from ingesting one plastic item.

From that moment on we knew we had to do something with this. So we started to look what was already there as alternative to wet wipes and decided to take a totally different approach.

Instead of trying to come up with a decent alternative for wet wipes we decided to set the bar much higher...From now on our goal was and is:

SIGNIFICANTLY IMPROVE THE WET WIPE EXPERIENCE ALL TOGETHER.

To accomplish that we needed to know why so many people use wet wipes and if we could improve those positive characteristics.

We came up with this list:

- Wet Wipes do the job. They clean much better than regular toilet paper, period.

- They do not tear easily so one feels comfortable using them without awkward accidents.

- Due to the reasons above one is done much faster and leaves the bathroom with a more fresh feeling.

- Skin irritation is less with wet wipes.

Now a list of the cons of regular wet wipes to complete the analysis (sorry of the terminology).

- Wet Wipes are thin and are easily soaked with excrement getting through to the other side.

- Wet wipes need to be stored in an enclosure to prevent them from drying out. That enclosure needs to be opened by hand which is unhygienic.

- Wet wipes containers do not look really nice in your bathroom.

- Wet wipes clog sewers.

- Wet wipes polluting our beaches and oceans

With this knowledge we could set our goals which are :

- A system that can apply a nourishing, protecting and Cleansing lotion that prevents skimpiness.

- The applicator must be easy to dose on regular toilet paper.

- The lotion must be of such viscosity that regular toilet paper will not get soaked.

- The system must look nice and well integrated in every bathroom.

If we could meet those goals we would actually have a system that improves over the regular wet wipe experience, making them obsolete.

So first we needed to have a test setup for testing different kinds of application systems and different kinds of lotion.

The first test unit that provided in these testing demands was designed and 3D printed.

As we had no patent we could only do the first tests within our family so we became test subjects.

All of us where obliged to write one test report a week about both lotion and applicator.

This was obviously a bit awkward as that experience is kind of a private endeavor. As a child you get potty trained and after that you are on your own and the experience becomes a very personal one.

So questions like "how much toilet paper per wipe do you use" and "Do you use a wet wipe every time or do you first do some dry runs" are answered with a little giggle at first.

We had a lot of fun with the awkwardness and after 3 months we gained all the knowledge we needed. Even in the first weeks it became obvious that this system was here to stay. especially our son was skeptic at first but within a week he said goodbye to regular wet wipes and was fully devoted to the NR-2 system. "It is just softer and it works better" was the response of Mr. hardcore wet wipe user. Now we could finally get rid of the bin that collected the used wet wipes after the sewer disaster. A very unhygienic bin I might ad.

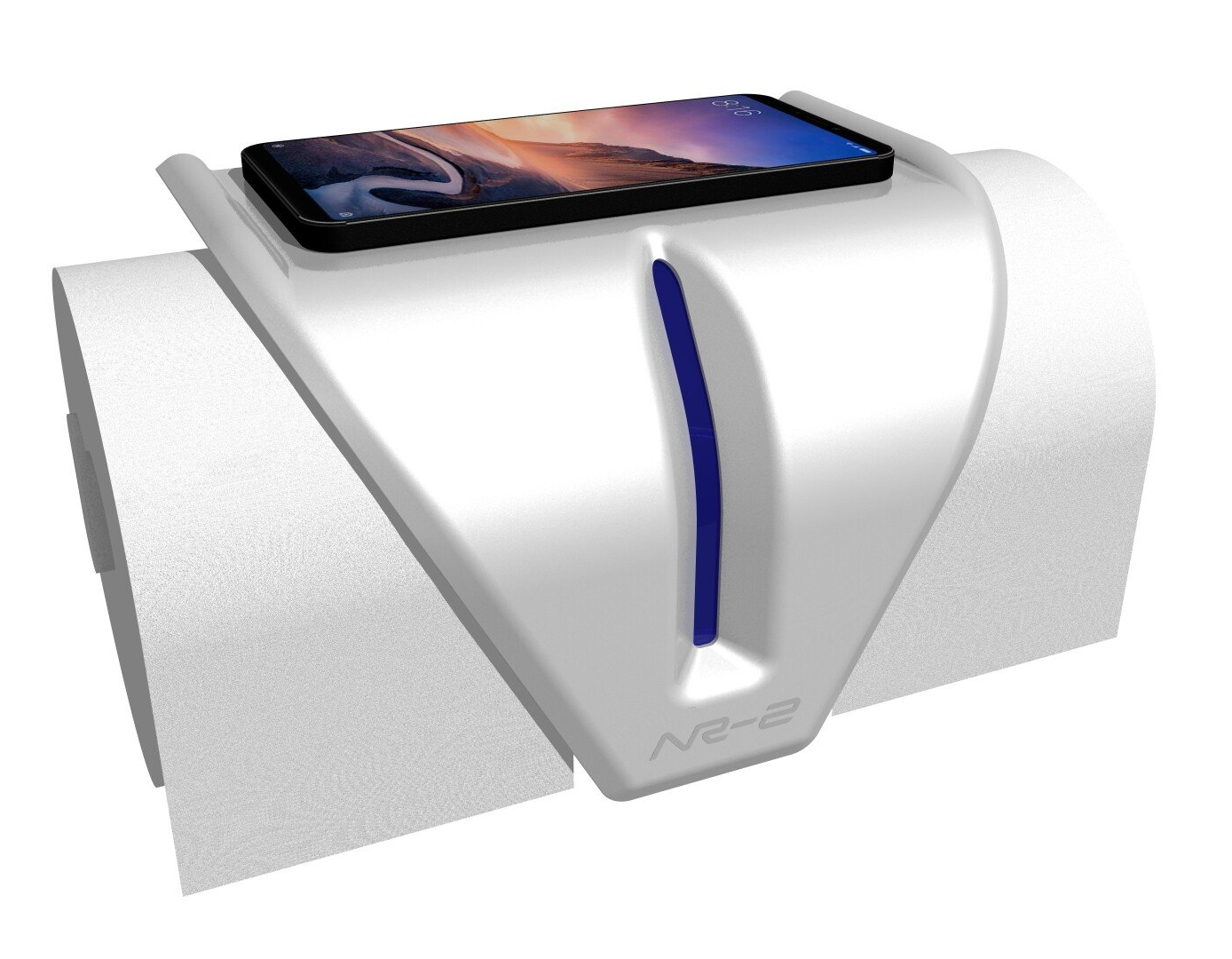

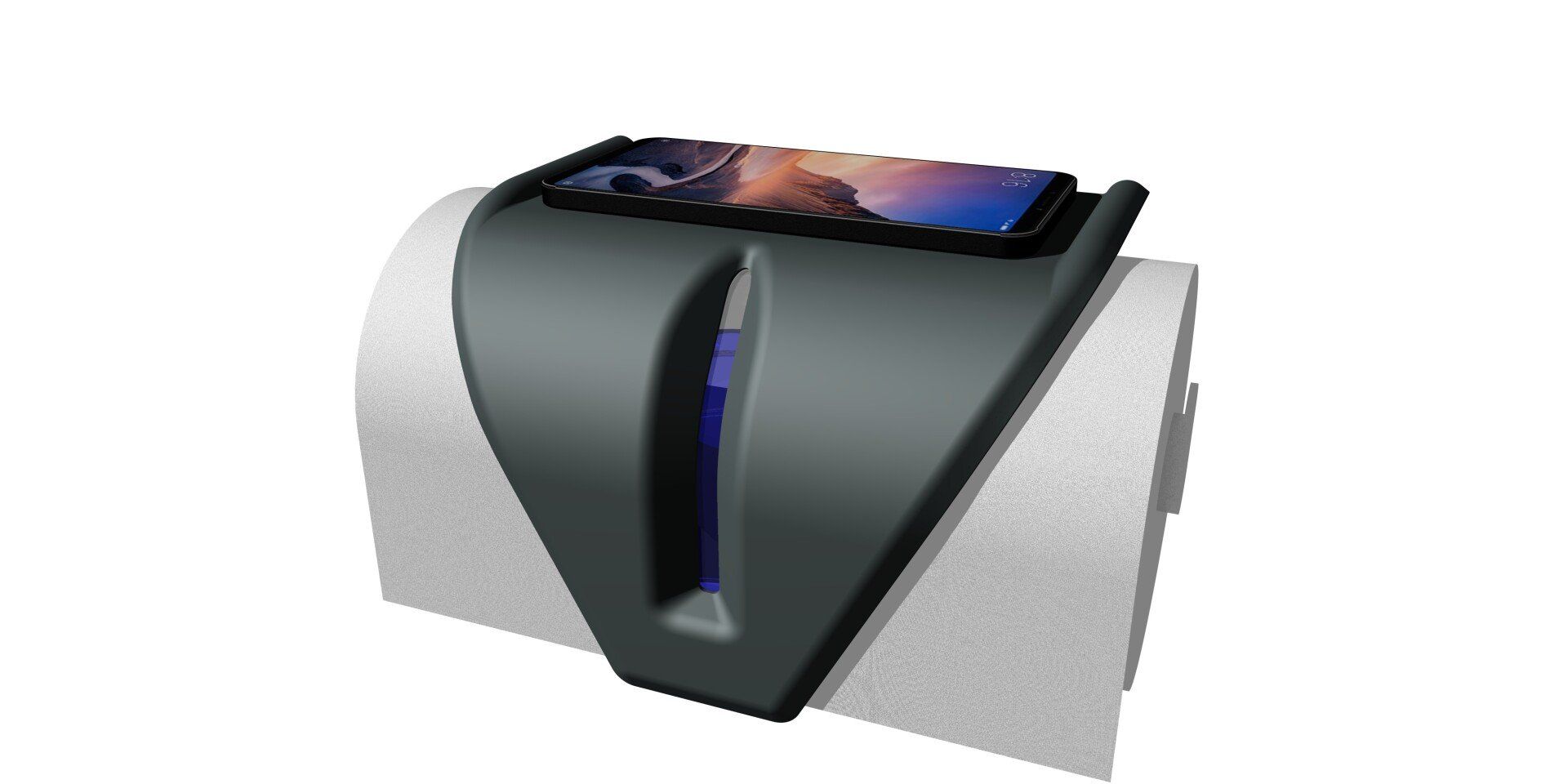

Anyway after the first weeks of experiencing the NR-2 we knew it was a good system and we started to design a few models to give it a better look and put in some extra features like a double roll setup etc.

When designing prototypes that will be close to the actual product, it is important to keep in account production methods as they will have effect on how the end result looks. Injection molding needs certain angles in the parts to be able to eject the part from the mold. Steel parts need to be folded and welded in such way that the pricing of the part stays within the stated goal etc. etc.

In other words this is a time consuming period of the project with a lot of communication between us designers and the producers of the parts.

We are now past the first of those phases and the first pre production evaluation parts are made and delivered.

Now that we have the pre-production units it is time to test it on a bigger test group. We have the honor to have on in our bathroom and now other families have it too. so far so good. We already have some minor adjustments on the "to do" list like the lock of the bottle that needs to lock better.

So this is the phase that we take out the last glitches and produce the last pre production parts to verify the design and then.......PRODUCTION

We will keep you posted on our progress.

The NR-2 is developed to replace wet wipes. First reason for us was because they clogged our sewer due to the fact that our son was a huge fan of wet wipes. We ended up digging out our sewer pipe and completely replaced it as the blockage was too bad to unclog.

At that time I was thinking that it might be an idea to come up with an alternative so I went on an online expedition to see how bad these wet wipes really are......

I WAS SHOCKED!!

after seeing this video of THE GUARDIAN...

Turns out that wet wipes are containing plastic and they are not disintegrating like normal toilet paper causing all kinds of horrible disasters like bringing down whole water treatment plants and polluting oceans and beaches.

Wet wipes appear to be jellyfish for marine life like sea turtles so they eat the wet wipes.

Sea turtles eat large numbers of jellyfish. (which look like wet wipes).Researchers at Commonwealth Scientific and Industrial Research Organisation (CSIRO) in Australia found that a turtle had a 22 percent chance of dying from ingesting one plastic item.

From that moment on we knew we had to do something with this. So we started to look what was already there as alternative to wet wipes and decided to take a totally different approach.

Instead of trying to come up with a decent alternative for wet wipes we decided to set the bar much higher...From now on our goal was and is:

SIGNIFICANTLY IMPROVE THE WET WIPE EXPERIENCE ALL TOGETHER.

To accomplish that we needed to know why so many people use wet wipes and if we could improve those positive characteristics.

We came up with this list:

- Wet Wipes do the job. They clean much better than regular toilet paper, period.

- They do not tear easily so one feels comfortable using them without awkward accidents.

- Due to the reasons above one is done much faster and leaves the bathroom with a more fresh feeling.

- Skimpiness has less with wet wipes.

Now a list of the cons of regular wet wipes to complete the analysis (sorry of the terminology).

- Wet Wipes are thin and are easily soaked with excrement getting through to the other side.

- Wet wipes need to be stored in an enclosure to prevent them from drying out. That enclosure needs to be opened by hand which is unhygienic.

- Wet wipes containers do not look really nice in your bathroom.

- Wet wipes clog sewers.

- Wet wipes polluting our beaches and oceans

With this knowledge we could set our goals which are :

- A system that can apply a nourishing, protecting and Cleansing lotion that prevents skimpiness.

- The applicator must be easy to dose on regular toilet paper.

- The lotion must be of such viscosity that regular toilet paper will not get soaked.

- The system must look nice and well integrated in every bathroom.

If we could meet those goals we would actually have a system that improves over the regular wet wipe experience, making them obsolete.

So first we needed to have a test setup for testing different kinds of application systems and different kinds of lotion.

The first test unit that provided in these testing demands was designed and 3D printed.

As we had no patent we could only do the first tests within our family so we became test subjects.

All of us where obliged to write one test report a week about both lotion and applicator.

This was obviously a bit awkward as that experience is kind of a private endeavor. As a child you get potty trained and after that you are on your own and the experience becomes a very personal one.

So questions like "how much toilet paper per wipe do you use" and "Do you use a wet wipe every time or do you first do some dry runs" are answered with a little giggle at first.

We had a lot of fun with the awkwardness and after 3 months we gained all the knowledge we needed. Even in the first weeks it became obvious that this system was here to stay. especially our son was skeptic at first but within a week he said goodbye to regular wet wipes and was fully devoted to the NR-2 system. "It is just softer and it works better" was the response of Mr. hardcore wet wipe user. Now we could finally get rid of the bin that collected the used wet wipes after the sewer disaster. A very unhygienic bin I might ad.

Anyway after the first weeks of experiencing the NR-2 we knew it was a good system and we started to design a few models to give it a better look and put in some extra features like a double roll setup etc.

When designing prototypes that will be close to the actual product, it is important to keep in account production methods as they will have effect on how the end result looks. Injection molding needs certain angles in the parts to be able to eject the part from the mold. Steel parts need to be folded and welded in such way that the pricing of the part stays within the stated goal etc. etc.

In other words this is a time consuming period of the project with a lot of communication between us designers and the producers of the parts.

We are now past the first of those phases and the first pre production evaluation parts are made and delivered.

Now that we have the pre-production units it is time to test it on a bigger test group. We have the honor to have on in our bathroom and now other families have it too. so far so good. We already have some minor adjustments on the "to do" list like the lock of the bottle that needs to lock better.

So this is the phase that we take out the last glitches and produce the last pre production parts to verify the design and then.......PRODUCTION

January 2023

It has been over a year since we last updated this page, so a lot has happened.

**Patent.**

After more than a year, it has finally happened... The patent has been granted, which means that the NR-2 system is indeed an innovative new system that brings unmatched advantages.

Production and sales of the NR-2 system started in May 2022 and have been very successful. We have received a lot of positive feedback from the many users of the NR-2, as well as suggestions for improving the system.

Of course, we did not ignore this and began implementing these suggestions into our current "flagship," the NR-2. We have also designed a new model that is smaller than the NR-2: the NR-2 Mini...

This is now also available for purchase in our webshop.

Below is a video about the updates from January 2024:

March 2025.

The European ban on plastic-containing wet wipes is getting a bit closer!!

We are very happy that State Secretary Chris Janssen supports a European ban on plastic-containing wet wipes. This is despite a motion against this ban receiving a small majority in the House of Representatives, with a justification that seems to directly contradict the explanations provided by experts.

These experts, including Waternet and Teeuwissen, clearly indicate that these wipes clog sewage systems and pumps. As a result, overflows must be opened, and these wipes end up in rivers and oceans. This applies not only to plastic-containing wet wipes but also to those wet wipes that the manufacturer claims are biodegradable and can therefore be flushed. Various tests from Waternet (link) prove otherwise. The societal costs of this are estimated to be between 22 and 55 million euros per year.

We want to take action.

A drop in the ocean? Perhaps. We are a small company in a small country like the Netherlands, and we can hardly compete with giants like Unilever. But does this mean we should do nothing? Absolutely not! We believe that every step counts. We have to start somewhere.

A great first victory would be if wet wipes are indeed banned. This would be a significant win for the environment, and we would like to contribute to that with our sustainable solution: the NR-2.

More than a glimmer of hope.

State Secretary Jansen has advised against the motion. According to him, there are no national rules on top of EU policy, as he wants to address it at the European level through amendments to the Single Use Plastic (SUP) directive. Therefore, it is still unclear whether he will fulfill the wish of the Parliament.

In the meantime, we are producing more and more NR-2 systems, meaning that more people are making the switch. We have been working on this for almost 3 years now, and with increasing success...

AND WE ARE PROUD OF IT!!!!!

SUPPORT OCEAN WILDLIFE